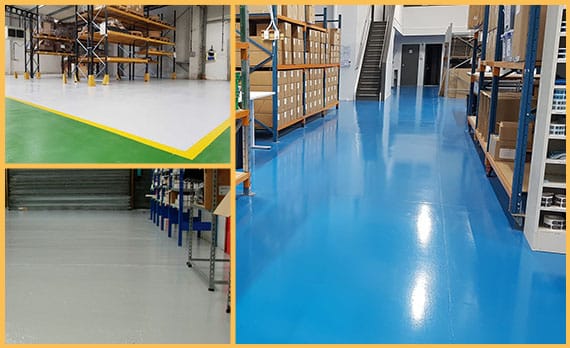

A high-gloss, self-smoothing epoxy floor finish that is compliant with CSM® (Cleanroom Suitable Materials) requirements, which provide continuous protection for concrete floors at thicknesses of between 2.0- 4.0mm. The cured material produces a dense, colourful, glossy surface and has excellent wear and abrasion resistance to floors subjected to high volume traffic.

Cleanrooms, laboratories, warehouses and storage areas and dry process areas where the floor is subjected to foot, trolley, pallet truck and rubber wheeled forklift traffic.

A three part solvent-free combination of epoxy resin, modified amine hardeners filled with specially graded and selected high crushing strength, chemically inert aggregates. The cured mortar offers an extremely high strength floor screed with exceptional resistance to the surface mechanical wear and attack from chemical spillage, is impervious and, at the same time, has a safe non-slip finish for personnel and vehicular traffic. It is laid by hand trowel as a durable chemical resistant screed at 3 to 6 mm thickness depending on the requirement. It is ideal for re-profiling worn and damaged floors when applied to concrete surface.

Substations, Loading bays, Workshops, Distribution centers, Laydown areas, Production halls, Power installations, Metal processing and engineering.